As one of the large-scale electromechanical equipment in the plastic processing industry, the injection molding machine has the advantages of large production scale, high consumption of raw materials and high production efficiency, creating great value and bringing a lot of convenience to people's lives.

In order to keep the injection molding machine in normal operation for a long time, we need to carry out daily maintenance and preventive maintenance of the injection molding machine.

Doing a good job in the maintenance of the injection molding machine can improve the service life of the injection molding machine to a certain extent and reduce the cost of the enterprise.

However, for the same injection molding machine, why some companies are in full condition after only a few years, while some companies can continue to operate normally, which is actually closely related to the maintenance of the injection molding machine. Now let's talk about the lubrication of the injection molding machine in detail.

Lubrication of manual or semi-automatic plastic injection molding machines

1. Lubrication of the gear box

Any failure of the gearbox will affect the quality and quantity of processing. For the hardened spur gear and quenched and tempered shaft in the box, a uniform and reliable lubricating oil film should be ensured. Generally, the oil cup and splash lubrication method can meet the lubrication requirements.

2. Lubrication of injection parts

The function of the injection part is to heat the plastic evenly to the injection temperature through the electric heating ring, and the injection pressure is formed by the screw pressure of the pressing rod. The lubrication of the pressing rod generally adopts the lubrication methods such as oil cup and oil rope.

3. Lubrication of the clamping part

The clamping part is composed of pulley, lead screw, nut, vise and so on. Adjust the position of the striker on one side of the vise to match the travel switch on the machine base, and control the feed stroke of the screw, so that the vise can open and close the mold. Because the friction nodes of the screw and nut are small, the oil film is easy to be squeezed and cracked, so the lubricating oil should have good oiliness. Generally, L-AN46 oil or HL hydraulic oil is used to lubricate through the oil cup and oil rope.

4. Lubrication of the base part

The sliding guides on the machine base are generally made of cast iron. Because the load and speed of the guide rail are not large, the use of mineral lubricating oil can ensure a certain boundary oil film. Generally, after lightly touching the guide rail surface with your hand, if you can see oil traces on your hand, it means that a layer of oil film has been maintained on the guide rail surface.

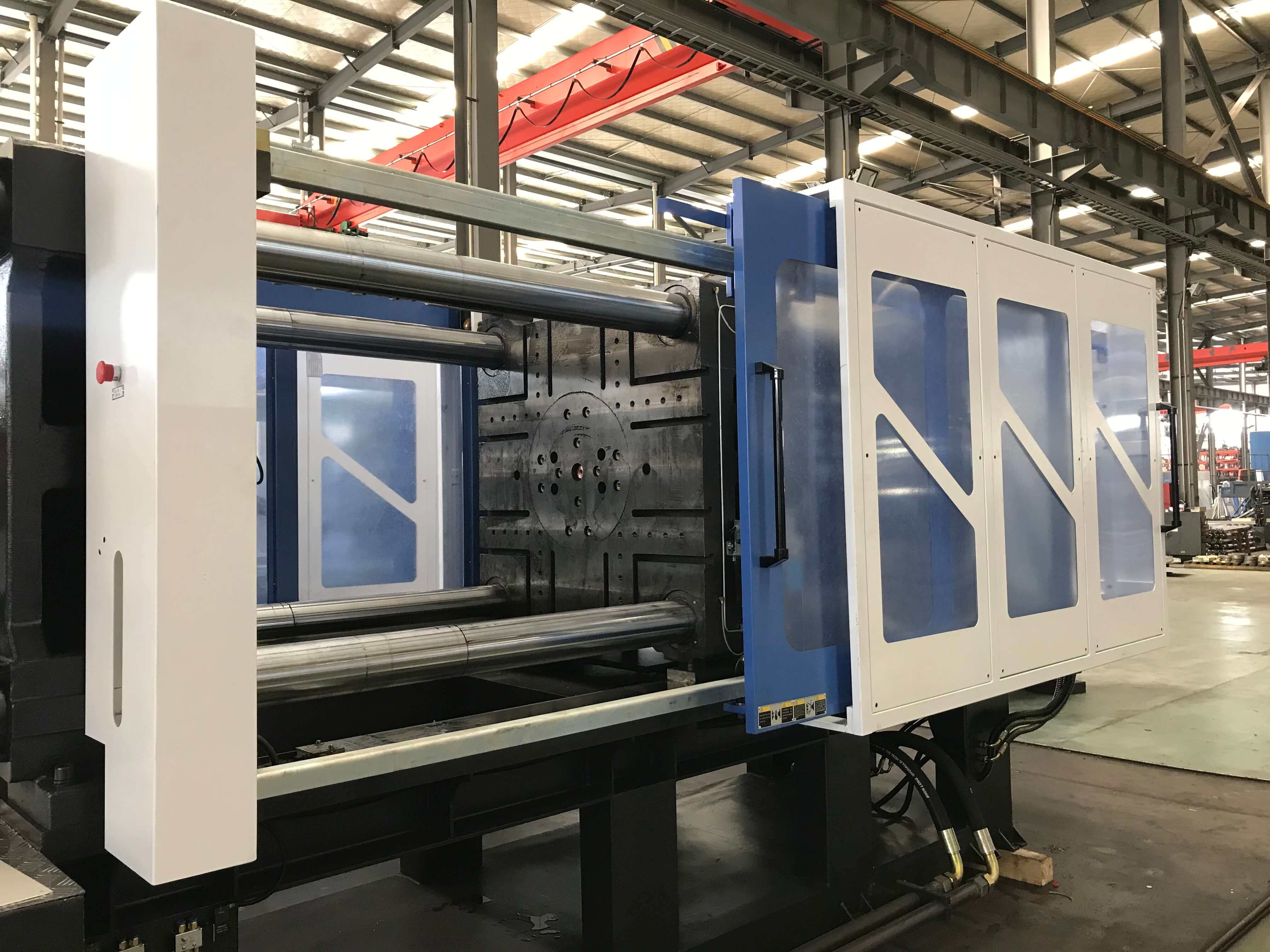

Lubrication of automatic hydraulic injection molding machine

The characteristics of this injection molding machine are: high degree of automation, stable performance, electrical and hydraulic interlocking protection devices, high precision and complex structure.

1. Lubrication of the injection part

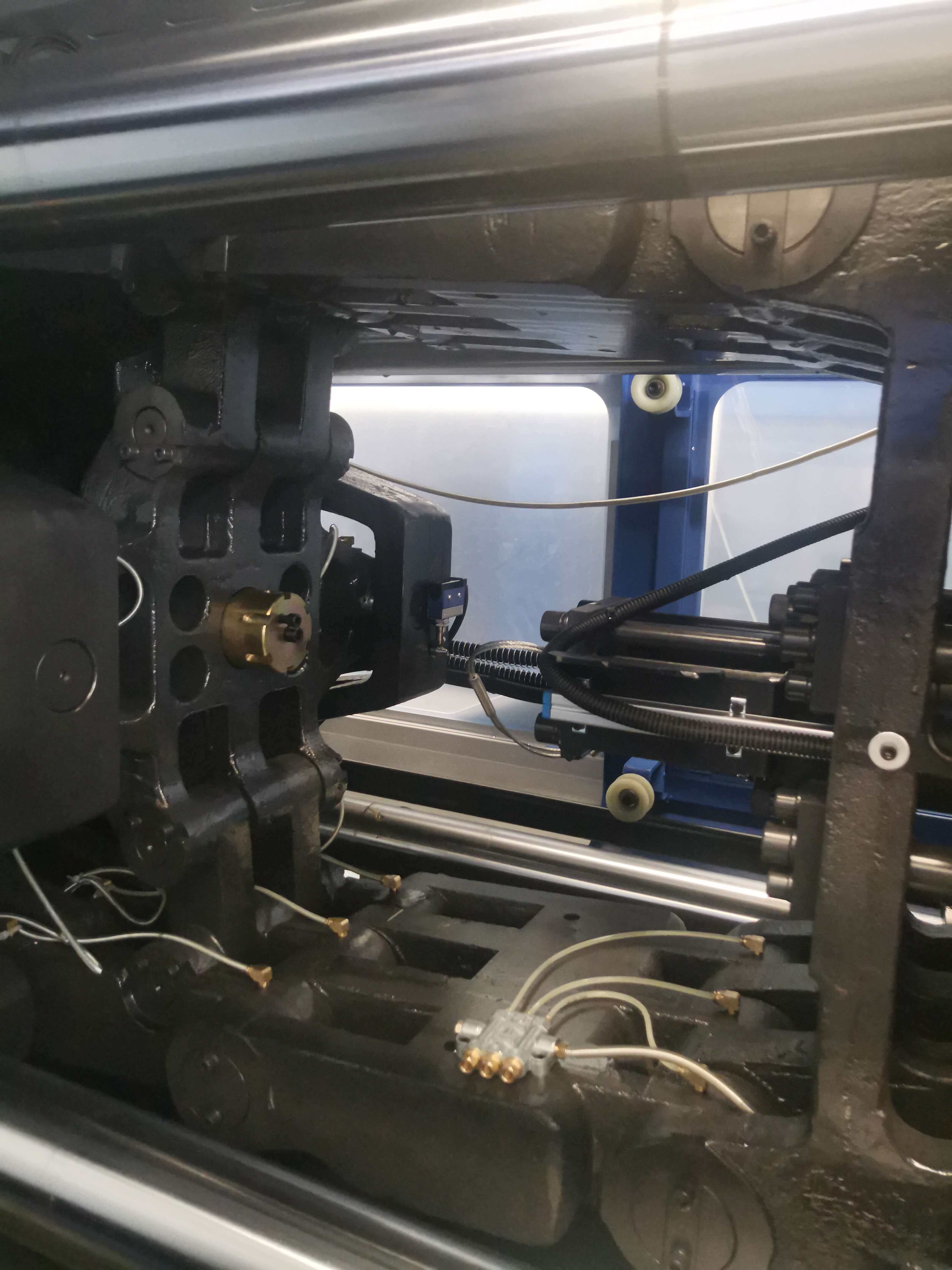

Since this part is the key component for injection molding, the double oil cylinder pulls the pre-plastic variable speed gearbox, pushes the screw through the gearbox, and injects the uniformly plasticized plastic into the film cavity. The movement is relatively frequent, and there is an electric heating device, so the lubrication system must be strictly implemented. The main lubricating parts of this part:

Add L-AN46 full-loss system oil to the injection seat and the rack rail surface, once per shift.

Add L-AN46 full-loss system oil on the guide rail surface at the bottom of the gearbox (roller), once per shift.

Add grease to the rotation center, about 0.3L.

Add about 10L of L-AN46 full-loss system oil to the transmission gearbox.

2. Lubrication of moving parts

Die-moving adopts hydraulic power and direct-pressure liquid filling device, with simple structure, reliable action and few lubrication points. The main purpose is to ensure the formation of a lubricating oil film on the four guide posts, which can be lubricated by L-AN46 mechanical oil through the oil cup and oil rope.

3. Lubrication of the motor

Most of the automatic hydraulic injection molding machines are driven by multiple motors. During daily lubrication, the motors should be lubricated as required.